Pretty cool Ron !

Taxidermy Talk Administrator

Stehling’s Taxidermy LLC http://www.stehlingstaxidermy.com

Taxidermy Insider / Learn Taxidermy Online http://www.taxidermyinsider.com

920.650.5457 a.n.stehling@gmail.com

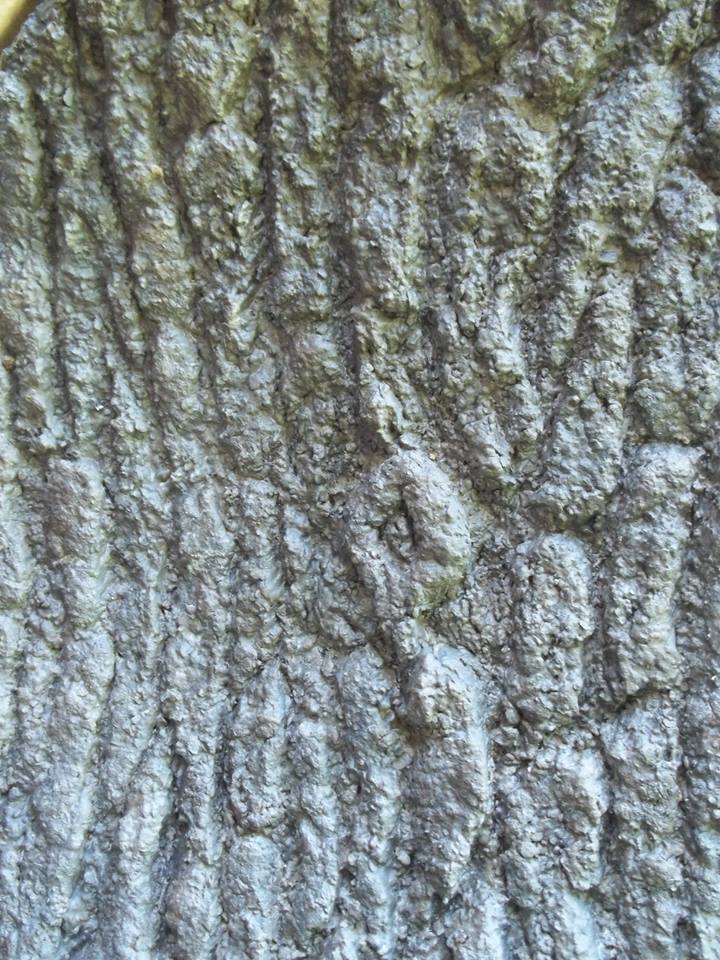

I used rock mix from McKenzie. Applied it to the entire surface I wanted covered first. About a half inch thick. Then, I hand sculpted the bark into the rock mix. After I had the sculpting done. I took a wet sponge and softened the rock texture up a bit. This tightened the bark pattern up a bit also. Then I sprayed a base coat of Moss green on it. Sponged numerous colors onto it, till I got what I was looking for , for color. Then gave it a black wash, to bring out the detail and sealed with flat clear.

I was just playing around actually. This is a personal piece and I always wanted to try and make a bark backing for a wall ped.

Ron

Looks good Ron, I’ll give you the way I do bark textures less time involved therefore more profit , buy some Latex 47 , mold different kinds of bark right from the trees, even different areas of the tree I’ve done oak, pine, maple so far , I also make my own mâché mix for doing it but the mâché mix from Nicolas Lindsey mâché works great too

June 10, 2012

Offline

OfflineAfter the Texas Convention I came home and did this driftwoodt from one I used on a customer’s mount, the picture is not the best by you can see the result.

I used Dermagrip’s latex to cast the driftwood and them pored a bond-fiberglass resin mix to mold it. then used the paints to get the details to the driftwood, need to use more brown to replicate the original…

Log In

Log In