[avatar user=”D.Price” size=”thumbnail” align=”center” link=”file” /]

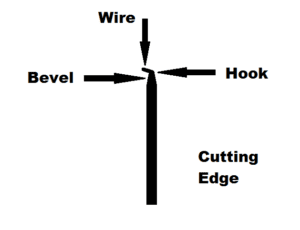

HOW THE CUTTING EDGE WORKS

Tuning your fleshing blade is an art in itself, above and beyond running the machine. To understand this process you must first know how the cutting edge or wire works.

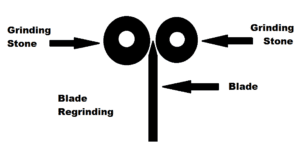

First lets touch on how the wire is created to begin with. The blade is attached to a machine that grinds both sides of the edge at the same time. This process uses two different stones that create even bevels on both sides of the blade.

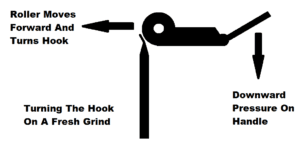

Once the edge is razor sharp it is rolled to an angle slightly less than 90 degrees. This is done by using a mechanical device that has roller and a tension spring in it and a handle for controlling the pressure applied to the bevel.

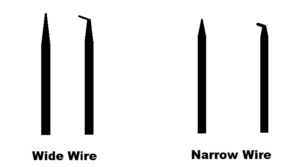

You can turn the edge in different sizes by controlling the bevel size and pressure applied when turning. The wider the wire the thinner the lip will be. This causes the edge not to last as long. For that reason I prefer a narrower, heavy edge. This will also allow you to control the cut better by tuning the edge.

HOW TO TUNE THE CUTTING EDGE

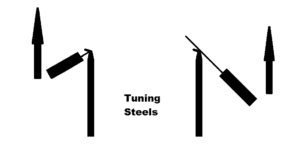

You want to lift or open the wire with your left hand. You do this by lightly placing the short bullet shaped steel under the wire and slowly lifting. This will manipulate the edge to where it will cut deeper.

You close or turn down the edge with your right hand By laying the longer steel on top of the blade. Now lightly lift your right hand to close off the cut size. This is a very delicate process, you do not want to be heavy handed with this.

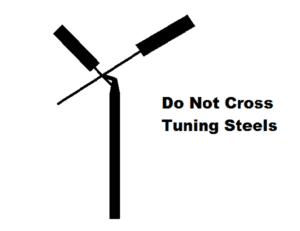

DO NOT cross your steels while tuning. This will cause friction and heat that will only prematurely end the life of the cutting edge.

This is an art that can be learned with the right guidance and knowledge. I go into much deeper and live demonstrations in my online video series “Mastering The Fleshing Machine A-Z PLUS”. These videos show you how it is done in the commercial tanneries every day. They are a must have if you own a round knife or fleshing machine.

DP